Spink Controls

We are India’s leading Instrumentation company driven by latest Technologies

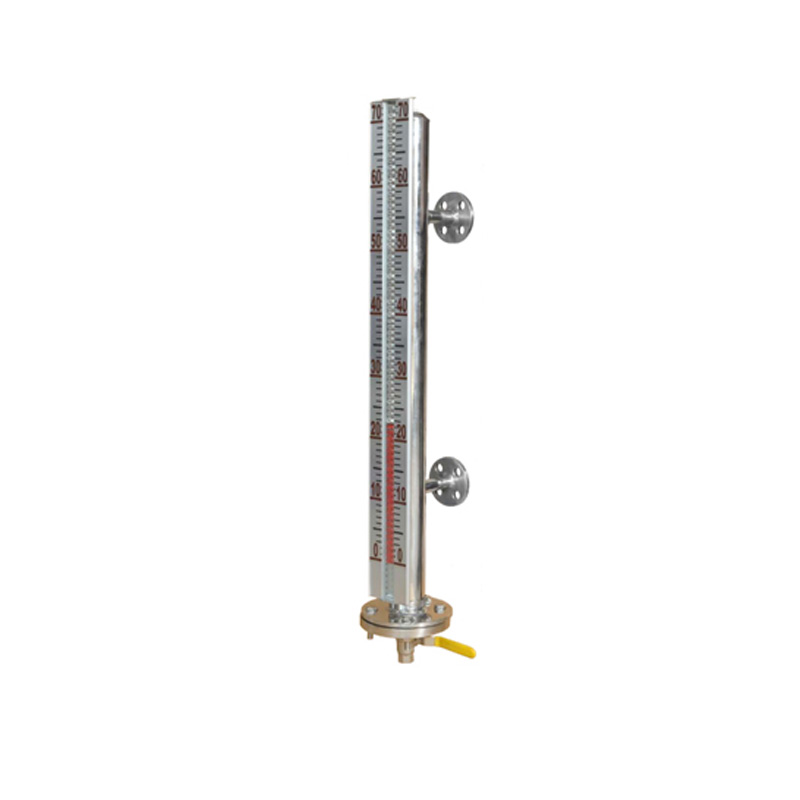

MAGNETIC LEVEL INDICATOR

SERIES : SC / L – 001

SERIES : SC / L – 001

Magnetic Level Indicator Operates on principles of magnetic field coupling, to provide fluid level information. Float chamber is typically constructed with non-magnetic pipe having a process connection that matches the vessel connections. Float size and weight are determined by the process fluid, pressure, temperature, and the specific gravity of the process fluid. Float contains magnets to provide a 360° magnetic flux field.

Bi-Colour Flapper Design

Indicator system consists of a Bi-Colour Flapper equipped with magnets mounted on a rail inside the housing. As the level starts rising or falling, the magnetic Float also travels with the liquid level in the non-magnetic chamber. The magnetic interaction between the magnets in the Float and the Bi-Colour Flapper causes each Flapper to rotate 180°.

Follower Capsule Design

Indicator system consists of a colour Follower Capsule that moves in a glass tube inside the housing. As the level starts rising or falling, the magnetic Float also travels with the liquid level in the non-magnetic chamber. The magnetic interaction between the magnets in the Float and the Capsule causes the Capsule to travel along with the magnetic Float.

For applications where high and low electrical signals are required, adjustable limit switch assemblies are provided.

APPLICATION

Building industry materials, cement, sand, lime, etc.

Foodstuff industry, milk powder, flour, salt, food grains, etc.

Plastic industry, powder, granular etc.

Timber industry, chemical and mining, etc.

MEASURING SYSTEM

The complete system, FCFORKHARP- 2000 series, consists of:- The sensing probe of Vibrating Fork and The Electronic Switching unit

Categories: level, Level Transmitter

ENGINEERING SPECIFICATION:

- Mounting Type : Top / Side

- Indicator length (C/C distance) : 300 to 6000 mm

- Indicator system : Bi-colour Flapper / Follower Capsule

- Housing for Indicator : SS Housing for SS Flapper, Aluminum Housing for Aluminum Flapper Follower Capsule – Glass Tube in Aluminum/SS Channel

- MOC of Bi-Colour Flapper : SS 304 / Aluminum

- Float Chamber : SS 304. SS 316, SS 316L, PP others on request.

- Float : SS 304. SS 316, SS 316L, PP others on request.

- Scale : Aluminum / SS / Acrylic Engraved in mm

- Process Connection : Flange / Thread / Triclover

- Vent : 1/2 ” Plugged / 1/2 ” Ball valve

- Drain : 1/2 ” Plugged / 1/2 ” Ball valve

- Maximum Temperature : 180 ° C for PP, 150 ° C for SS.

- Maximum Pressure : 2 kg/cm² for PP, 10 kg/cm² for SS more pressure on request.